DigitalCeramicRoofTiles: an approach on preserving heritage buildings through additive manufacturing

2024/08/30

Master thesis

Hessenpark is an open-air museum dedicated to historical village life in our federal state. In addition to the preservation of historical objects of daily use and the cultivation of traditional craftsmanship, aspects of monument preservation also play a major role in its museum concept. So far, over 100 historic buildings worthy of protection have been saved from total demolition by relocating them to the museum grounds. However, the preservation of these buildings is constantly facing new challenges, whose solutions through AM are to be investigated.

The aim of this thesis is to investigate the extent to which 3D-printed tiles could be used to restore damaged roofs. Often, historical building elements are no longer available on the market. 3D scanning and modeling based on existing examples offers the potential to “reprint” such. In addition to the theoretical part, which describes the basics and working methods of heritage conservation and additive manufacturing, a practical investigation using the example of historical roof tiles is also to be carried out and evaluated as part of this work.

Supervisor: Dr.-Ing. Architekt Alexander Wolf

Master thesis

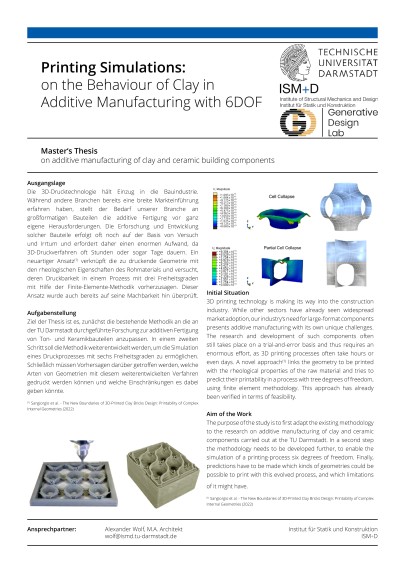

3D printing technology is making its way into the construction industry. While other sectors have already seen widespread market adoption, our industry‘s need for large-format components presents additive manufacturing with its own unique challenges. The research and development of such components often still takes place on a trial-and-error basis and thus requires an enormous effort, as 3D printing processes often take hours or even days. A novel approach(1) links the geometry to be printed with the rheological properties of the raw material and tries to predict their printability in a process with tree degrees of freedom, using finite element methodology. This approach has already been verified in terms of feasibility.

The purpose of the study is to first adapt the existing methodology to the research on additive manufacturing of clay and ceramic components carried out at the TU Darmstadt. In a second step the methodology needs to be developed further, to enable the simulation of a printing-process six degrees of freedom. Finally, predictions have to be made which kinds of geometries could be possible to print with this evolved process, and which limitations of it might have

Supervisor: Dr.-Ing. Architekt Alexander Wolf

Master thesis

The construction sector is, due to the sheer size of buildings as its final roducts, one of the largest emmiters of waste in the European Union. For much of this, the demolition of buildings is to be held accountable, but also during production of building components a significant quantity of surpluses and waste appears. While novel approaches attempt to recylcle shredded ceramics into new bricks, other leftovers still remain unused. The purpose of the study is to first explore the different kinds of wastes and surpluses, that occur during brick production. Also, their yearly occurence needs to be quantified. In a second step, different strategies need to be formulated to up-, down- or recycle these leftovers. Further, depending on the formulated strategies, experiments have to be carried out als a proof-of-concept for some of the strategies. Last, predictions have to be calculated on how much economic and environmental impact the up-, re- or downcycling of the production leftovers could have.

Supervisor: Dr.-Ing. Architekt Alexander Wolf

Institut für Statik und Konstruktion

Generative Design Lab

Generative Design Lab

The content of this page is only available in German.

Please go to German version of this page